PrimaTape was developed to wrap welds, plug-in or push-in fittings retrospectively on underground pipelines. It is simple to process and can be done directly on the construction site with no additional equipment required.

PrimaTape provides the joint with a high level of mechanical protection so that the excavated material can be reused to fill the excavation pit.

PrimaTape is a fabric coated with special mortar that is easy to apply on the construction site. Due to the environmentally friendly composition of the material, the use in drinking water protection zones 1,2 and 3 is permitted. A test certificate according to W 347 is available.

APPLICATION AND PROCEDURE

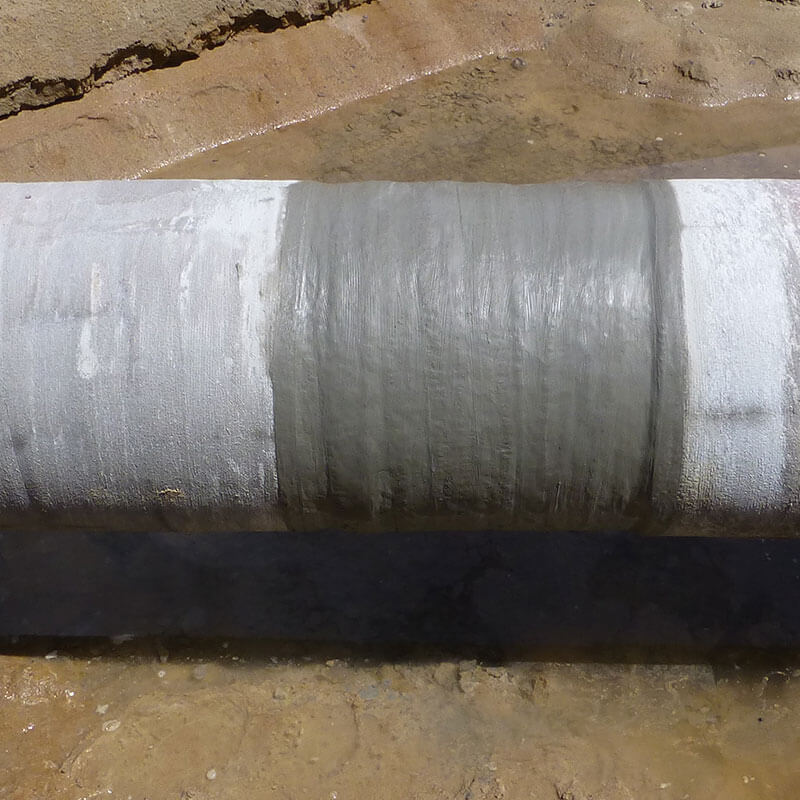

Application using the example of a fibre cement-coated pipeline DN 150

Post-coating of a DN 500 welded joint and an elbow

Before/after

Packaging units

PrimaTape has a width of 12 cm and a length of 6 m. One roll weighs 0.7 kg. One box contains 12 rolls; a pallet is packed with 45 boxes.

Shelf life

Shelf life is 6 months after delivery note date if stored in a dry place.

Time until load-bearing capacity

The recoated area reaches full strength after 48 h (at 20°C). Higher outside temperatures accelerate the curing process.

Processing time

4 to 10 minutes, depending on the amount of water added and the outside temperature.

PROPERTIES

- Easy to use and suitable for construction sites

- Resistant to exposure class XA2

- High impact resistance (tested according to DVGW worksheet GW 340)

- Can be used in drinking water protection zones (tested according to W347)